When people think about saving money, they usually think about cutting costs. Usually, there are two routes they take. The first – and the notorious one – involves getting rid of anything that’s not essential to profitmaking. The second – and the one we like – involves turning up the brain power.

Optimization software is the derivative of that brain power. It shows where the company can spend less without rigorous changes. This means you get to save money by finding out where you are leaking resources, without reducing the quality of what you do.

This new way isn’t just about keeping up with others or following the latest trends. Optimization software can bring down material waste, reduce manpower hours, and enhance product quality. All of which contribute to a healthier bottom line.

This article explores four compelling use cases from different industries where optimization software has proven to change the way they do business. Yes, in reducing wasted efforts and materials, but even more so in leaders’ receptiveness towards the change.

1. When a waste-heavy paint operation goes to waste

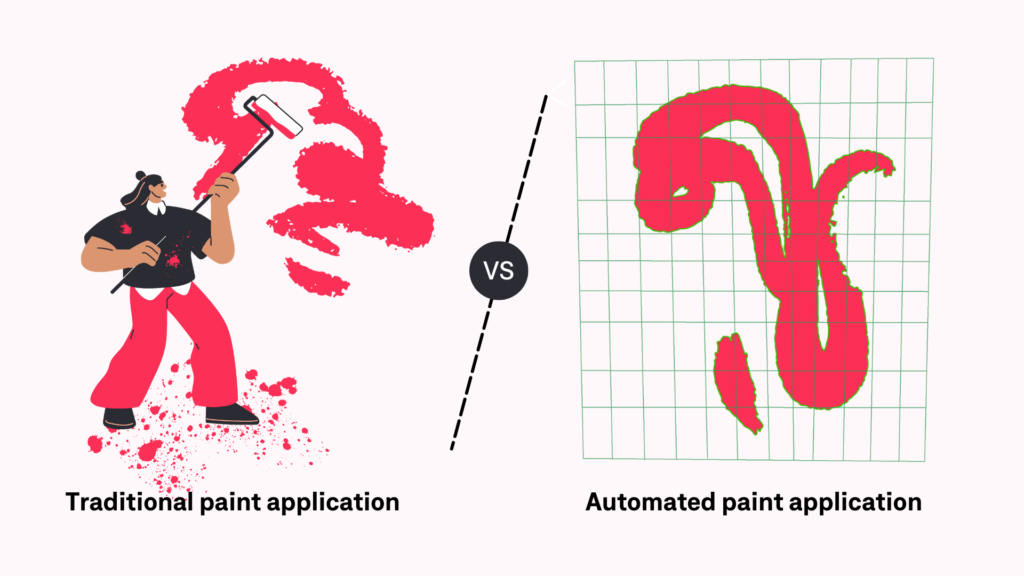

One of the examples of optimization software that piques interest is found in the manufacturing industry. Particularly in the automation of paint processes.

Traditional paint applications in manufacturing can be highly wasteful. For starters, a significant amount of paint material is lost to overspray. Think of wasting 5 spray cans to finish off street art when just two would do. This scenario is as common as machinery in the manufacturing processes we’ve seen in companies.

This is where precision robotics, guided by a solid understanding of the painting process, is setting new standards.

By implementing advanced robotics equipped with software that meticulously controls and adjusts the paint spray in real-time, manufacturers can drastically reduce waste. These systems precisely calculate the amount of paint needed, adjusting the spray mechanisms to cover complex geometries without excess.

It’s well known how software development is driving more sustainable practices. This not only cuts down on the spray material costs by minimizing waste but also significantly reduces the environmental impact of the painting process. Why? Well, there’s lots of waste associated with the painting process – think liquid waste in the form of preservatives, acetones, benzenes, or solid waste that arises during dispersion, filters that need changing with more spray paint used, and the transport of fluids.

The benefits extend beyond just material savings. Such precision leads to a higher quality finish, reduced rework, and faster production times, which further drive down operational costs.

2. Not wasting a single glance on documents

In a busy office, employees are often buried with paperwork. Worse yet, the heavy computer setup masks the fact that they’re still doing things manually – click here, scan there, click send, do it again… They spend hours manually eye-gazing for data, often making mistakes that need correcting. Go ahead and guess how this slows down an already heavy-stomping cogwheel.

Searching through documents for a single piece of information is one instance where this problem is evident.

In sectors like legal, finance, and healthcare, managing paperwork can be both time-consuming and prone to human error. Intelligent Document Processing (IDP) systems represent a significant advancement in handling these challenges.

For instance, the intelligent document processing solution we created recently offers a vivid example of how AI can make this anything but daunting.

Instead of converting the documents manually, using Ctrl+F to find pieces of information, and finally making sense of everything they just did… Employees can delegate this strenuous work. The system finds key information for you, delivers results in milliseconds, offers clear explanations, and automates the following steps, streamlining the entire process.The efficiency gained through such systems allows employees to focus on higher-value tasks. Just imagine how this leads to an overall increase in productivity. Additionally, faster and more accurate data processing improves service delivery, enhancing customer experience and competitive advantage.

3. Intelligent routing saves more than just gas

A few of the Net Group’s previous clients like Invaru and Ehituse ABC are running online stores. Each day, dozens of packages need to get to customers who are eagerly waiting.

Now, if your delivery routes aren’t smart, drivers might get stuck in traffic jams. As a result, they burn extra fuel, and their customers end up frustrated because their orders are late. Recently we shared a story of Best Buy’s Christmas inventory nightmare which highlights the same problem.

This smart tool looks at things like traffic patterns and weather, making sure drivers avoid delays. It suggests the quickest paths and best delivery times, so not only do packages arrive faster, but you also save money on fuel. Needless to say, you also help the planet a bit by cutting down on emissions.

Plus, if something unexpected pops up, like a road closure, the software adjusts the plan in real-time. This means less stress for both you and the drivers. In the end, it also means happier customers who get their purchases on time.

One such case study highlights how AI-driven optimization software optimized route planning and inventory management. Swift Logistics’ partnership with RTS Labs led to a 30% improvement in delivery efficiency and a 40% reduction in stockouts, significantly boosting customer satisfaction and profitability.

4. Maximising crop yields with precision farming

Precision farming is a game-changer in agriculture. The whole point of it is to turn every square meter of soil into a data point to optimize resource use and boost productivity.

Imagine a farmer, who once relied on intuition and tradition to guide his farming decisions. Now, the farmer uses a digital tool that crunches data from satellites, drones, and ground sensors to tell him exactly when to water, fertilize, and protect his crops against pests or bad weather.

The farmer would not just save time. Every drop of water and every gram of fertilizer would count, which means less waste and higher yields from the same piece of soil.

To bring this closer to home, let’s look at a real-world example. John Deere has integrated AI and Optimization Software into their agricultural equipment. They’ve developed systems that equip machines with sensors and cameras that analyze grain quality in real time as crops are harvested. The tools allow them to identify and adjust for variables affecting crop yield. In doing so, Deere is able to significantly reduce the use of chemicals (by up to 70%). Now think of the effect this has on the environment, crop quality, and eco-friendly trends that customers are increasingly looking for.

What could innovative tech do for you?

As we’ve seen through these examples, introducing the right technology can be a game-changer. It’s not just about cutting costs—it’s about making every decision count towards a smarter, more efficient operation.

Now, think about what this could mean for your own business. What opportunities might you uncover with the right software? What operations are costing you way too much money? What would be the ideal scenario for some of these operations?

Whatever the answers are, just bear this in mind. In our time, technology has the power to support solutions that seemed impossible a few years back. So, what will you do with it?

Similar insights

Which Software Development Process Is Best for Your Company?

10/02/2026

How To Know If Your Business Is Ready To Scale Internationally

21/01/2026

8 Hybrid Commerce Mistakes Companies Repeat in 2026

13/01/2026

Smart Workflows: AI Tools and Tips for Busy Leaders

16/12/2025

Supply Chain Attacks: Rethinking Third-Party Trust

10/12/2025

Choosing the Right Tech Stack in Uncertain Times

25/11/2025

How to Pitch and Get Your Ideas Approved at Work

12/11/2025

12 AI Cyberattacks That Made CEOs Very Cautious

21/10/2025

14 Books Smart Tech Leaders Are Reading This Fall

07/10/2025

Let the success

journey begin

Our goal is to help take your organization to new heights of success through innovative digital solutions. Let us work together to turn your dreams into reality.